11-07-2018, 07:45 PM

(This post was last modified: 11-07-2018, 07:47 PM by Phil Thien.)

A couple of enormous real-world work assignments have wound-through, and I'm back to make good on my commitment to deliver a 1/4" doweling jig.

One thing I've learned is, a bunch of shorter 1/4" dowels, a multidimensional array if you will, is a pretty great alternative to many other forms of joinery, including larger/deeper dowels.

First, ease: I've now standardized on 1" long dowels, so I can pretty much set the bit depth using a stop collar once, and forget it. I don't need larger dowels or longer dowels, because I'm using MORE dowels. And I only will need one dowel size to stock, going forward.

Second, strength: I've been testing to destruction and it seems a lot of smaller/shorter dowels is actually stronger than fewer larger/deeper dowels. I was hoping for almost as strong. My best guess is that distributing the stress over a wider area of the joint is pushing the envelope on the typical failure mode (where the stock itself just fractures apart).

Third, speed: Drilling 1/4" holes that are 1/2"-ish deep is really fast, even in challenging types of lumber. Chips from drilling fir, for example, can be a challenge to evacuate from holes when drilling larger/deeper. A 1/4" D 1/2" deep hole is not a problem in this regard. It is much much faster/easier drilling twelve (12) 1/4" holes than four or five 3/8" holes that are 1" to 1-1/2" deep.

I don't know of any other doweling jig that can do anything like this, not without having to jump through quite a few hoops. And it would be nowhere near as fast.

The astute observer will note that the fastener holes in the template are now pocketed. With the screw heads recessed, I can use a larger drill guide block, improving perpendicularity.

I'm also using a "real" 1/4" drill bushing. They aren't inexpensive, but will each joint needing more dowels, I figured it was worthwhile.

I'm still tweaking a couple of things. Like, the sandpaper on my fence is scraping-up the surface of the workpieces. I need finer-grained sandpaper. Most joints would be sanded but as you can tell form the pics, the alignment is so good that it might take more work to get the scratches from the sandpaper out, than to flush-up the joint.

Also want to tweak a couple of the dimensions a little more, to make setting the fence maybe a little more intuitive using stuff we already have in our shops.

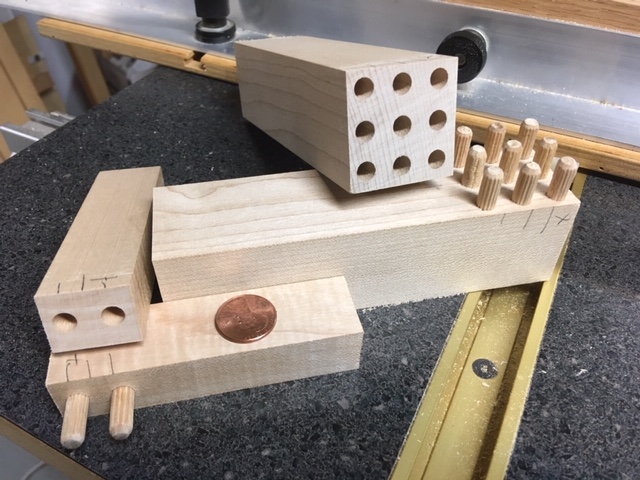

But here are some pics so you guys know I'm actually going to get this done.

First pic shows the jig and some 1-1/4 x 3-1/4 ("dressed 2x4") stock I use for making tool stands and workbenches. I've got twelve dowels in this joint. I've tested similar joints to destruction and found I need quite long lengths in order to get enough leverage to destroy the joint.

Here is that same joint assembled. Piston first, reference edges nicely aligned.

My current drill guide block. I thought of making something fancier, but this one works well and probably approximates my final design.

A joint in some 3/4 x 1" stock and some 1-1/2" square stock. Terrific fits.

As you can see, the alignment is great, but you can see my scratches being left by my sandpaper. I need to get some different (finer) sandpaper grits and see which works best.

One thing I've learned is, a bunch of shorter 1/4" dowels, a multidimensional array if you will, is a pretty great alternative to many other forms of joinery, including larger/deeper dowels.

First, ease: I've now standardized on 1" long dowels, so I can pretty much set the bit depth using a stop collar once, and forget it. I don't need larger dowels or longer dowels, because I'm using MORE dowels. And I only will need one dowel size to stock, going forward.

Second, strength: I've been testing to destruction and it seems a lot of smaller/shorter dowels is actually stronger than fewer larger/deeper dowels. I was hoping for almost as strong. My best guess is that distributing the stress over a wider area of the joint is pushing the envelope on the typical failure mode (where the stock itself just fractures apart).

Third, speed: Drilling 1/4" holes that are 1/2"-ish deep is really fast, even in challenging types of lumber. Chips from drilling fir, for example, can be a challenge to evacuate from holes when drilling larger/deeper. A 1/4" D 1/2" deep hole is not a problem in this regard. It is much much faster/easier drilling twelve (12) 1/4" holes than four or five 3/8" holes that are 1" to 1-1/2" deep.

I don't know of any other doweling jig that can do anything like this, not without having to jump through quite a few hoops. And it would be nowhere near as fast.

The astute observer will note that the fastener holes in the template are now pocketed. With the screw heads recessed, I can use a larger drill guide block, improving perpendicularity.

I'm also using a "real" 1/4" drill bushing. They aren't inexpensive, but will each joint needing more dowels, I figured it was worthwhile.

I'm still tweaking a couple of things. Like, the sandpaper on my fence is scraping-up the surface of the workpieces. I need finer-grained sandpaper. Most joints would be sanded but as you can tell form the pics, the alignment is so good that it might take more work to get the scratches from the sandpaper out, than to flush-up the joint.

Also want to tweak a couple of the dimensions a little more, to make setting the fence maybe a little more intuitive using stuff we already have in our shops.

But here are some pics so you guys know I'm actually going to get this done.

First pic shows the jig and some 1-1/4 x 3-1/4 ("dressed 2x4") stock I use for making tool stands and workbenches. I've got twelve dowels in this joint. I've tested similar joints to destruction and found I need quite long lengths in order to get enough leverage to destroy the joint.

Here is that same joint assembled. Piston first, reference edges nicely aligned.

My current drill guide block. I thought of making something fancier, but this one works well and probably approximates my final design.

A joint in some 3/4 x 1" stock and some 1-1/2" square stock. Terrific fits.

As you can see, the alignment is great, but you can see my scratches being left by my sandpaper. I need to get some different (finer) sandpaper grits and see which works best.