Posts: 4,182

Threads: 0

Joined: Feb 2001

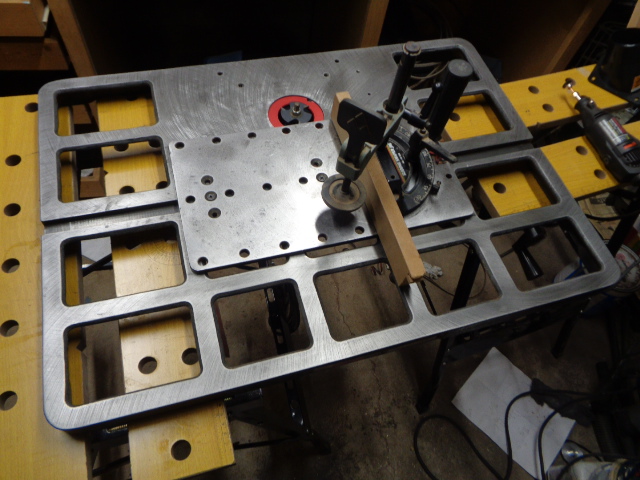

I have a couple of pieces of Corian 30 x 42 that I am thinking about using to make a some router table tops. This stuff is heavy and stiff. there is no flex in it what so ever. The top side very smooth. I like router lifts but do not like fitting a lift on a plate into s top. I would rather mount the lift to the actual top of the table like I did with the shaper table top. I made the plywood top this way because of the webbed top. No matter how good the dust collection is, some will escape and I didn't want it falling through the webbing and into the cabinet . The cabenite was not made at the time of the picture

Let me give you a little more information before I get to my questions. First the fence can be mounted to a different piece of the top so the Corian doesn't need to be the size of the whole top as seen in the picture below.

I prefer to use shaper jig, see picture below, for certain cuts like coping cuts, so I like a miter slot.

But just because I like miter slots doesn't mean they are necessary. I like using a shaper jig and I have 2. But others have different ways of doing things and I would like to know the general conscience if a table should or should not have a miter slot.

Also I am getting used to having the amount of table out in front of the cutter. I still find it a little awkward having to reach that far. What distance between the cutter and the front of the table do you find the most comfortable? Now there is a difference between what you have and what you would like.

And lastly how wide would make you table if making a new one?

Posts: 12,459

Threads: 0

Joined: Aug 2003

Location: Wapakoneta, OH

My table is a variation of Norm's, and I must have lucked out. The width is 41" and the front edge to the center of the router is 12"; both have worked out to my liking. I've used this table for over 20 years and now find is showing it's age. When I build a new one it will be exactly the same. I did put a miter slot in, but can probably count the number of times I've used it with the fingers on both hands. That might be the one difference in a new table, skip the miter slot (for me).

I started with absolutely nothing. Now, thanks to years of hard work, careful planning, and perseverance, I find I still have most of it left.

Posts: 2,041

Threads: 1

Joined: Feb 2009

Location: Mechanicsville, Md

I've worked with Corian and other solid surface material for close to 40 years. I don't see any reason not to make a top out of it, if that's what you want. A couple of things, no sheet of solid surface is perfectly flat. It usually comes 30" wide. Take a straight edge and lay across your pieces. The edges will dip down slightly. If you want a piece that is close to being the same thickness, cut 1/2" off of each edge, that'll get you close. Do the same if you have an end of a sheet. As for the finished size, I'm thinking maybe 36" square. If I were making a top, I would get a sheet of plywood, and silicone the Corian to it. Do not put globs of silicone down, spread it out with a small notched trowel or spreader. Typically, this is not done, however, since you want the router table top to be as flat and true as possible, the silicone needs to be of uniform thickness. Allow the silicone to set as long as possible before continuing. These are not typical solid surface methods, you are not doing a typical solid surface top. After the silicone cures, then cut your grooves in it. Break all edges when done. Enjoy your new router table, it should work great.

I no longer build museums but don't want to change my name. My new job is a lot less stressful. Life is much better.

Garry

Posts: 4,182

Threads: 0

Joined: Feb 2001

12-11-2023, 06:08 PM

(This post was last modified: 12-11-2023, 06:13 PM by tablesawtom.)

Yes I know that any sheet goods are not perfectly flat. But thank you for your tips on how to prepare it. I wasn't sure if I was going to put a backer board on or not and your tips made me decide to do so. It also helps support the front if I do a miter slot.

I checked out the shaper slot and it is 14 inches from the front to the center of the cutter. I think that 14 is a little to much but it is what it is. I checked out 12 inches and found it to be a really nice distance. I am not sure if I do not like 10 inches better. I am still up in the air on it. The shaper top is 27 wide. My table saw is 27 front to back and they are selling a lot of add on router table tops that are that dimension.

I was hoping to hear from others on what they like.

I have enough material to make 4 tops and I am planning on trying to sell them when finished.

Tom

Posts: 2,041

Threads: 1

Joined: Feb 2009

Location: Mechanicsville, Md

Please keep us posted on your decision. I enjoy seeing what others make.

I no longer build museums but don't want to change my name. My new job is a lot less stressful. Life is much better.

Garry

Posts: 4,182

Threads: 0

Joined: Feb 2001

12-12-2023, 11:02 AM

(This post was last modified: 12-12-2023, 11:07 AM by tablesawtom.)

This is where I am to date. I have two sheets of Corian, 30 x 40. One is supporting the CNC I bough a couple of years ago. I decided this is the year ( winter) I learned to use it, but that is a different story.

The second sheet I have decided to cut in half and make two tables. I have two Jessem router lifts that fit the Bosch or PC 690 routers. If it fits others I do not know. I took the plate into work and had inspection chart the 8 holes so now I know the exact location of them. I can put them on the Bridgeport milling machine just like I did with the shaper table. The mill has digital read out so I can duplicate the hole pattern.

I am going to back it up with 3/4 plywood but the lift itself will be bolted directly to the bottom of the Corian. I will also machine the bottom of the Corian so to preserve perpendicularity and prevent any possibility of binding.

That leave me with 2 tops basically 20 by 30. I did some checking when I did the shaper top as far as how big to do the center hole because of raised panel bits. I am setting it up for the smaller diameter raise panel bits because the big dogs will not fit in the lift. I kind of like the 20 inch wide top. it gives me room at the back of the table for slots so a fence can be mounted and so on.

That is why I am wondering how wide most of your router tables are. I need some extra material to make inserts out of. I was thinking of Corian because I would have the correct thickness if I made the top narrower. but I can use just about anything to make the inserts. If I learn to operate the CNC, I could even use it to make the inserts. Needing it to make something is a great motivator.

Anyway I think his name is Fred, he likes 12 inches from the front. In picture one you can see my steel table top and that distance is about 8 1/2 inches from the front. That has been my main go to table for the last 35 or so years. I am comfortable with that dimension, but I am not convinced the 10 inches wouldn't be better. And while I am writing this I decided to go the 12 inches. If I don't like it I can cut some off but I can't add if I decide I want more in front. So thank you Fred.

That still leaves me with width and whether or not to put in a miter gauge slot. I can go either way especially if it is backed up with plywood. Corian taps nicely so bolt it to the plywood around the slot. The only time I have ever used the miter slot is when making cope cut on the ends of door parts. It is extra work for not very much gain but. I would like to hear your thoughts on the matter. As well as on width.

I have already decided to use the two suggestions that have already been given. I am still out on the miter slot.

Tom

Posts: 1,664

Threads: 0

Joined: Apr 2005

Re miter slot I used a piece of laminated countertop so had plenty of depth. They make aluminum miter track which works pretty well for what I did, I don't think it would work with 1/2" solid surface, the sheet would be too shallow. My primary use has been cope cuts on door rails; I suspect that's the common use though I could make or buy a light duty shaper jig type thing.

Posts: 4,182

Threads: 0

Joined: Feb 2001

Museumguy said to back it up with basically plywood and that would offer support for the miter slot.

I have a block with a Butten Head screw mounter in a block of Aluminum that is doweled on to the top so All I have to do is put the block on the router table top. I have a shaper jig that is set as square as possible so the distance of the end of the work piece is established permanently to the bearing surface of the copping g cutter. The only real set up I have to to raise or lower the cutter to height.

I also know that there are other types of copping jigs on the market that use a fence for location. Then a miter slot isn't necessary So My question is how many of you have gone in this direction? which make the slot not necessary.

Or now many like the slot verses not having the slot. And again what it the ideal width, that you would make the top if making, a router table. I have heard from a few but I would prefer to have more of a general consensus from more if possible.

Tom

Posts: 23,963

Threads: 2

Joined: Sep 2003

Location: Missouri

I'd sure try some corian if I had any. Me being out of the cabinet business since 2010, I've lost contacts and have no idea whether corian can even be purchased in this area anymore. You can get granite out the wazzoo though.

I'm down to having (2) double router cabinets now, since getting rid of my (3) single router cabinets.

So not much need for another router top, but I would most likely replace the laminated PB tops I made for the present cabinets, if I had some corian laying around.

Steve

Mo.

I miss the days of using my dinghy with a girlfriend too. Zack Butler-4/18/24

The Revos apparently are designed to clamp railroad ties and pull together horrifically prepared joints

WaterlooMark 02/9/2020

Posts: 2,493

Threads: 0

Joined: Oct 2005

(12-20-2023, 07:26 PM)Stwood_ Wrote: I'd sure try some corian if I had any. Me being out of the cabinet business since 2010, I've lost contacts and have no idea whether corian can even be purchased in this area anymore. You can get granite out the wazzoo though.

I'm down to having (2) double router cabinets now, since getting rid of my (3) single router cabinets.

So not much need for another router top, but I would most likely replace the laminated PB tops I made for the present cabinets, if I had some corian laying around.

I just got quite a few large scraps of Corian from a countertop fabricator for what amounted to lunch money. He has a guy that uses the colored stuff to make mosaics. I got a bunch of black grey, cream and white stuff for jigs and stuff.

"There is no such thing as stupid questions, just stupid people"

|