02-24-2024, 04:36 PM

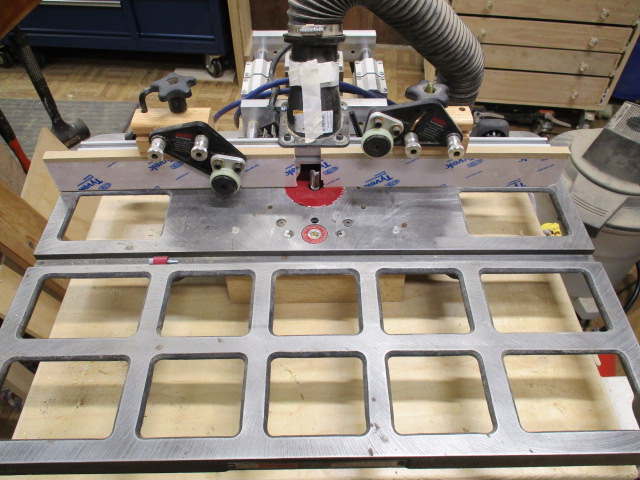

It has taken my a while but all I have left to do to finish my router table is to make two drawers and put on drawer facing. It has been to cold in my unheated shop to work since the middle of November and it it still only takes about 15 minutes for my fingers to start hurting as of today, but it won't be long now. It has been frustrated not being able to take pictures but today my daughter came over and got me up and running so here are a few pictures.

[attachment=50003]

Some things that need to be changed are:

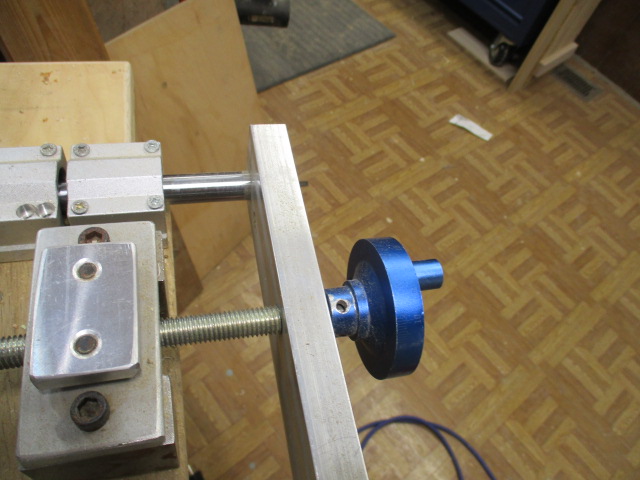

The fence needs to be moved back to allow more room behind the cutter when all the way back. The Jessem wheels do not work with this fence system. Because the fulcrum point to fare away from the actual fence. Because of the distance and play in the linear bearings, the fence lifts up and I lost the down ward pressure. I think a person with an Incra system will have the same problem. Maybe if I lift up on the fence before setting the roller height it will help I will see when it warms up. Or possibly a way to clamp down.

I love MDF inserts on the fence I have some stick on plastic to help the wood to slide past easier. What I really like is I can make a zero clearance fence easily. and the MDF doesn't come near dulling any cutter. Zero clearance inserts really show there worth when using door and rail cutters as well as slot cutting bits. It is easy to remove the MDF cut off the end and make a new zero clearance insert with a different cutter. I made extras.

I already posted pictures of the actual machining of the cast iron top a year or so ago if you would like to see them do a search.

Thanks for looking.

Tom

[attachment=50003]

Some things that need to be changed are:

The fence needs to be moved back to allow more room behind the cutter when all the way back. The Jessem wheels do not work with this fence system. Because the fulcrum point to fare away from the actual fence. Because of the distance and play in the linear bearings, the fence lifts up and I lost the down ward pressure. I think a person with an Incra system will have the same problem. Maybe if I lift up on the fence before setting the roller height it will help I will see when it warms up. Or possibly a way to clamp down.

I love MDF inserts on the fence I have some stick on plastic to help the wood to slide past easier. What I really like is I can make a zero clearance fence easily. and the MDF doesn't come near dulling any cutter. Zero clearance inserts really show there worth when using door and rail cutters as well as slot cutting bits. It is easy to remove the MDF cut off the end and make a new zero clearance insert with a different cutter. I made extras.

I already posted pictures of the actual machining of the cast iron top a year or so ago if you would like to see them do a search.

Thanks for looking.

Tom