03-21-2024, 02:54 PM

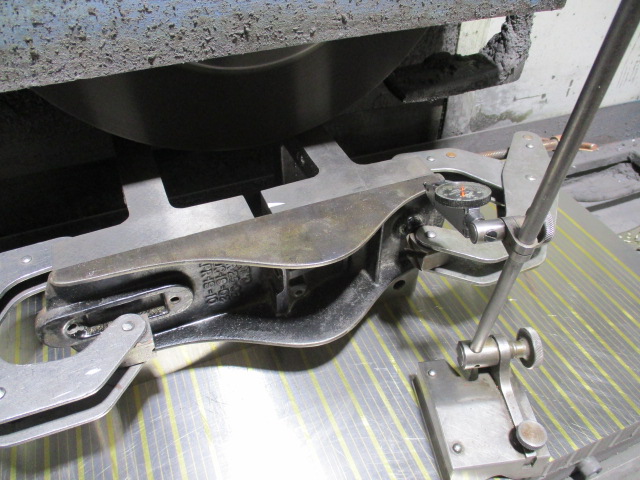

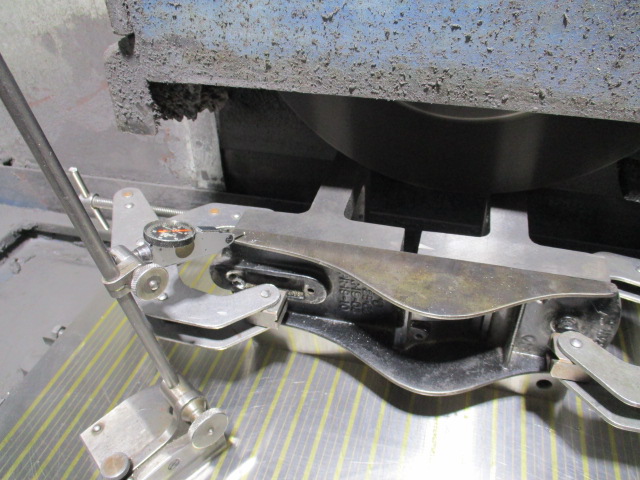

I wanted to show the 608 being ground bit I forgot the camera. I just got finished grinding a 4 1/2 so I thought I would show the steps because They are the same. Usually one machines the largest surface first, and then the sides. but in this case it has already been machined. I clamped the largest surface to my angle plates. Yow can see that two angle plates were used. The 608 was done the same way it is just that the angle plated were spaced farther apart. Then the first side that was ground was placed on the magnetic table and the second side was ground parallel to the first. Then the plane is flipped and the first side reground, usually only about 1 to 1 1/2 thousands will clean up every thing. Because the bottoms of the planes may or may not be flat, the clamps can distort the plane a little bit. This is my way of making the sides as parallel as possible and exactly the same thickness. It also gets rid of any possibility of any twist from clamping to the angle plate.

Next the plane is clamped in a precision vise and the bottom is ground. And trust me a precision vise is not just any ordinary vise vary accurate vise. When I did the 608 I used two vises, just like the two angle plates.

I spent just under 4 hours grinding this plane. I also had about 40 minutes travel tine and I wouldn't have spent the time to use a machine that is designed to do one thing which is to remove metal and if I thought I could use sandpaper and a piece of glass to flatten it, or a scrapper, a skill I do not have, I would have done so at my home. I know every body thinks they can flatten a plane but iron doesn't sand like wood.

Tom

Next the plane is clamped in a precision vise and the bottom is ground. And trust me a precision vise is not just any ordinary vise vary accurate vise. When I did the 608 I used two vises, just like the two angle plates.

I spent just under 4 hours grinding this plane. I also had about 40 minutes travel tine and I wouldn't have spent the time to use a machine that is designed to do one thing which is to remove metal and if I thought I could use sandpaper and a piece of glass to flatten it, or a scrapper, a skill I do not have, I would have done so at my home. I know every body thinks they can flatten a plane but iron doesn't sand like wood.

Tom