12-30-2023, 12:30 PM

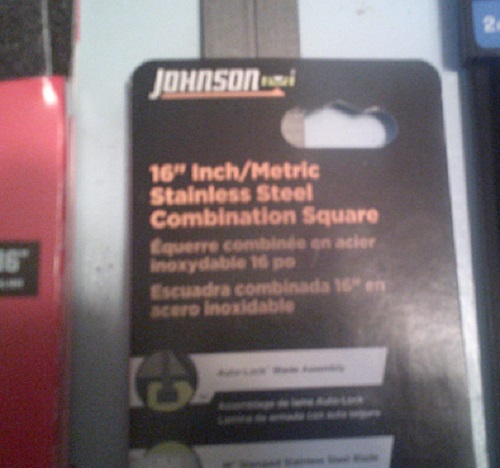

The blade in the New Combo Square...is 16" long...and is marked in both Imperial and Metric. Top of my bench is also 16" wide, counting the tool well.

Errands to run, today....Boss is being taken to Fazoli's for a Birthday Lunch by our Daughter.....after that? Will have to see how Lunch settles...

Panel trimming might happen, later? And, instead of trying to set the clock face panel into grooves...will be doing "Slips" all around...with a few spots of glue to hold the panel in place...

Need to bevel the top edges of the Base...

And add the feet case to be attached to the base with a couple "Glue & Screw Blocks" ...

Think either a 7' X7" squares for the front, or 7" x 9" rectangle....will see what the grain looks like in Panel #6, first...

Top of the case will also use the glue blocks....( go and look around inside those older Grandfather Clocks, sometime..)

Info on that Combo Square..

Means I now have a 6", a 12", and a 16" versions....YMMV, Of course...

Errands to run, today....Boss is being taken to Fazoli's for a Birthday Lunch by our Daughter.....after that? Will have to see how Lunch settles...

Panel trimming might happen, later? And, instead of trying to set the clock face panel into grooves...will be doing "Slips" all around...with a few spots of glue to hold the panel in place...

Need to bevel the top edges of the Base...

And add the feet case to be attached to the base with a couple "Glue & Screw Blocks" ...

Think either a 7' X7" squares for the front, or 7" x 9" rectangle....will see what the grain looks like in Panel #6, first...

Top of the case will also use the glue blocks....( go and look around inside those older Grandfather Clocks, sometime..)

Info on that Combo Square..

Means I now have a 6", a 12", and a 16" versions....YMMV, Of course...

Show me a picture, I'll build a project from that